Removal and Replacement Instructions for the VideoRay Pro 4

Vertical Thruster Propeller Kit

GTO-006LS-KIT

|

Copyright

Pro 4 Maintenance Manual, Novice 1.00.00 |

Copyright NoticeThis material is copyright protected. No material may be reproduced or transmitted in any form or by any means for any purpose without expressed written consent of VideoRay LLC. Copyright © 2015, VideoRay LLC - The Global Leader in Micro-ROV Technology |

|

Table of Contents

Pro 4 Maintenance Manual, Novice 1.00.00 |

Table of Contents

|

|

About this Document

Pro 4 Maintenance Manual, Novice 1.00.00 |

About this DocumentDocument ConventionsSeveral symbols are used throughout this documentation to add emphasis and to assist in relocating important information. The following table describes these symbols and their uses.

Beyond this DocumentThere is no substitute for experience and/or training, especially with respect to the real purpose for which you plan to use this equipment. We encourage you to explore options beyond the scope of these materials to expand your knowledge and skills necessary to support your applications. In addition to this documentation, VideoRay offers training and technical support and hosts a general user discussion forum and user image gallery. We also realize that collectively, users of our products spend considerably more time operating our systems than we do ourselves. Users also encounter more diverse operating environments across an extremely broad range of applications. We highly value this vast experience base, and invite and encourage you to share your experiences and suggestions with us. Please feel free to contact us by any of the methods listed below. Quality CommitmentVideoRay strives to design, manufacture, deliver and support the highest quality products and services, including this documentation. We have made every effort to ensure that this documentation is accurate and provides you with the most up-to-date information. If you find any errors in this documentation or have suggestions for improvements, each page contains a "Help us improve this document" feedback link in the left margin (you must be connected to the Internet to use this link).

DisclaimerThis document is deemed accurate at the time of its writing, however it is not a legal contract and the information contained herein should not be construed to represent any form of commitment. This document as well as the associated products and services are subject to change without notice. Online ManualThe full version of this manual is available online in the following formats:

|

|

How to Get Help

Pro 4 Maintenance Manual, Novice 1.00.00 |

How to Get HelpHelp for your Pro 4 is available through several channels. All Hours Self-Service / Crowd-Source Tools

Global Support

Regional Support

Training

Operational Strategies and Tactics SupportIf you need help understanding how to apply your system to a specific project, contact VideoRay or you local VideoRay dealer. We can provide guidance or help you find a certified consultant. |

|

Removal Procedures

Pro 4 Maintenance Manual, Novice 1.00.00 |

Vertical Thruster Propeller Kit Removal OverviewSkill level recommended: Novice Total time required: Approximately 4 Minutes Tools required: The following components must be removed: See the corresponding sections of this manual for instructions for parts other than the Vertical Thruster Propeller Kit. Notes:

|

|

2 - Vertical Propeller

Pro 4 Maintenance Manual, Novice 1.00.00 |

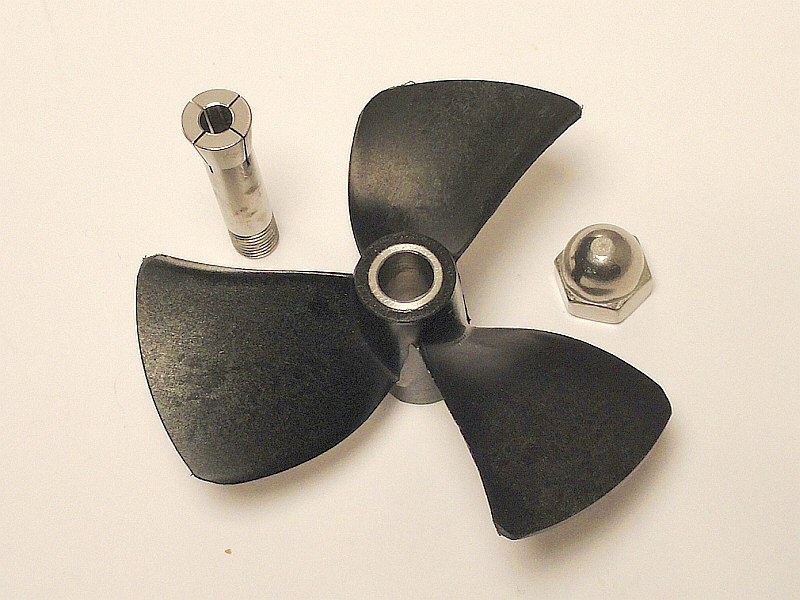

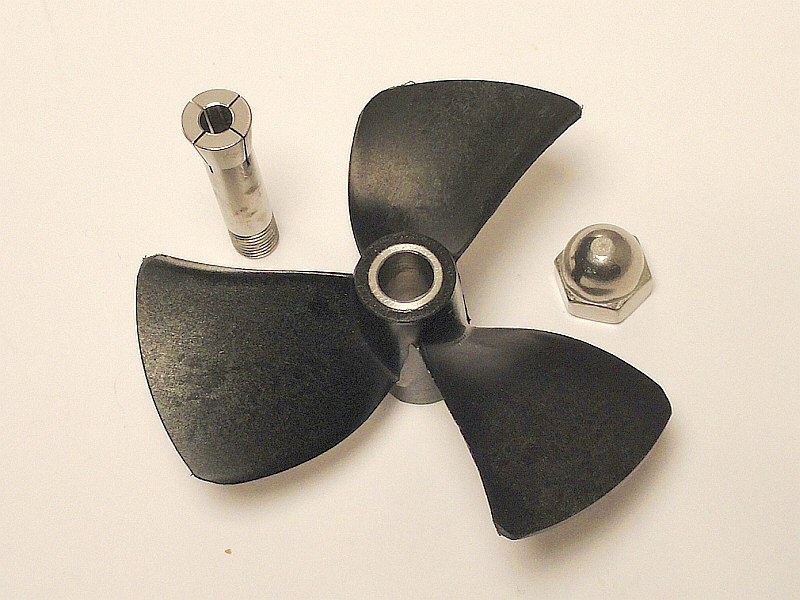

Vertical Thruster Propeller Kit Removal ProceduresTime required for this step: Approximately 2 Minutes Tools required for this step: Parts involved in this step: GTO-006LS-KIT Vertical Thruster Propeller Kit

Steps

Tips

The vertical propeller nut has right-handed threads. Turn the nut counterclockwise, when viewed from the top of the ROV, in order to loosen it. If the vertical propeller does not come off of the vertical thruster shaft easily after loosening the nut, tap the nut while pulling on the propeller hub. This should loosen the propeller collet and the propeller should slide free from the shaft. |

|

Replacement Procedures

Pro 4 Maintenance Manual, Novice 1.00.00 |

Vertical Thruster Propeller Kit Replacement OverviewSkill level recommended: Novice Total time required: Approximately 4 Minutes Tools required: The following components must be replaced: See the corresponding sections of this manual for instructions for parts other than the Vertical Thruster Propeller Kit. Notes:

|

|

1 - Vertical Propeller

Pro 4 Maintenance Manual, Novice 1.00.00 |

Vertical Thruster Propeller Kit Replacement ProceduresTime required for this step: Approximately 2 Minutes Tools required for this step: Parts involved in this step: GTO-006LS-KIT Vertical Thruster Propeller Kit

Steps

TipThe vertical propeller nut has right-handed threads. Turn the nut clockwise, when viewed from the top of the ROV, in order to tighten it. Check to make sure that the propeller turns freely. |